Press Release Originally Published:

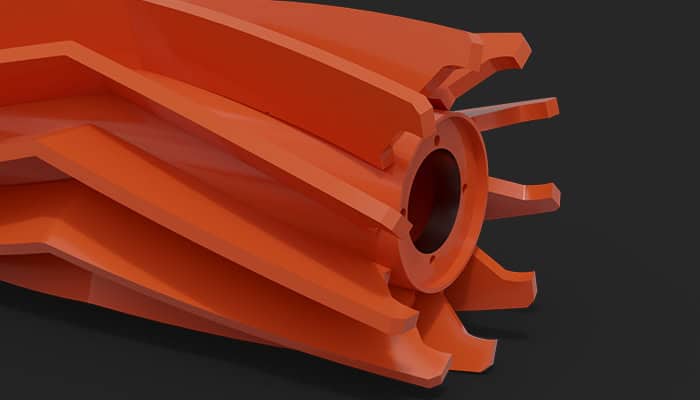

Morris, Minn. – Superior Industries, Inc., a US-based manufacturer and global supplier of bulk material processing and handling systems, reports its newly redesigned Chevron Pulley is now available in abrasion resistant (AR) steel.

According to the conveyor components manufacturer, the use of abrasion resistant steel in manufacturing of conveyor pulleys enhances their durability, especially in applications handling aggressively wearing bulk materials. This reduces maintenance costs, improves operational efficiency, and ensures consistent performance in demanding environments.

In another recent design update, Superior removed the rounded cap on the wings for standard CEMA and Mine Duty models. Now, the entire wing is a wearable feature, which significantly increases the lifespan of the Chevron Pulley in all applications. The rounded wing caps are still optional for Mine Duty Models.

Superior’s 2007 invention of the v-shaped Chevron Pulley revolutionized wing performance, offering benefits such as material deflection, reducing trapped material, minimizing belting damage, lowering noise, and being gentler on belt splices and clips compared to traditional straight wing pulleys.

For more information on Superior’s wing pulleys, visit the Chevron Wing Pulley page.